Introduction

Chemistry is the scientific study of matter, its properties, and the changes it undergoes. It explores the composition, structure, behavior, and interactions of substances. Chemistry plays a crucial role in understanding the world around us, as it helps explain the nature of materials, their physical and chemical properties, and how they can be transformed. It is often referred to as the central science, as it connects the physical sciences, such as physics and biology, and provides a foundation for understanding various other scientific disciplines. From understanding the composition of the air we breathe to developing new medications and materials, chemistry is vital in numerous scientific and technological advancements. By studying chemistry, scientists aim to uncover the fundamental principles that govern the behavior of matter, allowing for a deeper understanding of the natural world and the development of practical applications that benefit society.

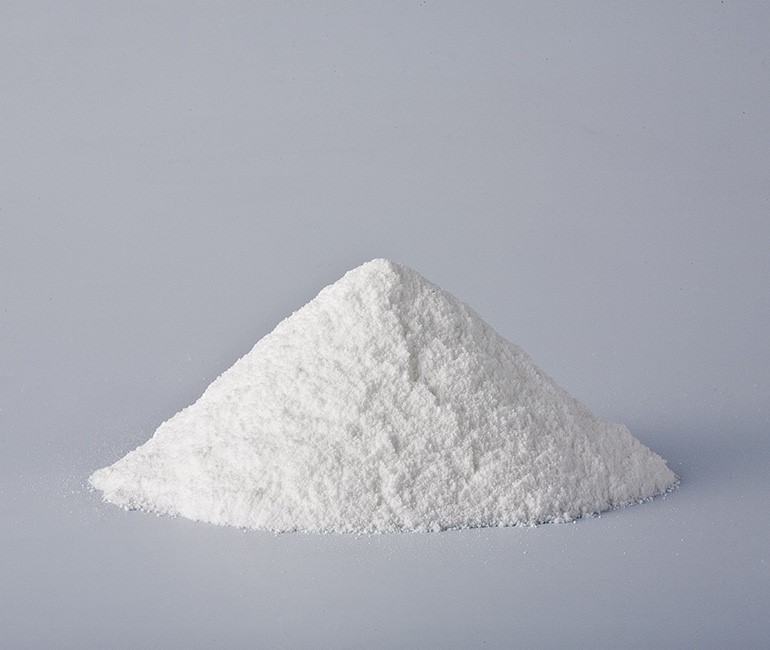

Properties of Aluminium Oxide

Aluminium oxide, also known as alumina, is a chemical compound with the formula Al2O3. It is a white, crystalline solid that occurs naturally as the mineral corundum. Aluminium oxide has several important properties in chemistry, including:

1. High Melting Point: Aluminium oxide has a very high melting point of approximately 2,000 degrees Celsius. This makes it suitable for use in applications that require high-temperature resistance, such as furnace linings and refractories.

2. Hardness: Aluminium oxide is a very hard material, ranking 9 on the Mohs scale of mineral hardness. This property makes it useful in various abrasive applications, such as sandpaper, grinding wheels, and cutting tools.

3. Insulating Properties: Aluminium oxide is an electrically insulating material, meaning it does not conduct electricity. This makes it suitable for use as an insulator in electrical systems, such as in power transmission lines or electronic devices.

4. Chemical Inertness: Aluminium oxide is chemically inert, meaning it does not readily react with other chemicals. This property makes it resistant to corrosion and erosion, making it useful in applications such as chemical reactors, catalyst supports, and lining for chemical storage tanks.

5. Thermal Conductivity: Aluminium oxide has relatively high thermal conductivity compared to other ceramics. This property allows it to efficiently transfer heat, making it suitable for use in heat sinks, catalytic converters, and other thermal management applications.

6. Optical Properties: Aluminium oxide is transparent to visible light and has a high index of refraction. This makes it useful in optical components, such as lenses, windows, and laser gain media.

Overall, aluminium oxide exhibits a combination of physical, electrical, and chemical properties that make it widely used in various industries, including metallurgy, ceramics, electronics, and manufacturing.

Uses of Aluminium Oxide

Production and Synthesis of Aluminium Oxide

In chemistry, aluminium oxide (Al2O3) can be produced and synthesized through various methods. Here are two commonly used approaches:

1. Bayer Process: The Bayer process is the most widely employed method for large-scale production of aluminium oxide. It involves several steps:

– Extraction of bauxite: Bauxite, which is an ore rich in aluminium oxide, is first mined and then purified to remove impurities.

– Digestion: The purified bauxite is dissolved in a hot sodium hydroxide (NaOH) solution under high pressure, resulting in the formation of sodium aluminate (NaAlO2).

– Precipitation: Carbon dioxide (CO2) gas is bubbled through the sodium aluminate solution, leading to the precipitation of aluminium hydroxide (Al(OH)3).

– Calcination: The aluminium hydroxide is heated at high temperatures, causing it to decompose and form aluminium oxide.

Overall, the Bayer process relies on extracting aluminium oxide from bauxite ore and further processing it to obtain pure aluminium oxide.

2. Chemical reaction: Aluminium oxide can also be synthesized through a chemical reaction between aluminium metal and oxygen gas (O2). This direct synthesis typically occurs under high temperature and in the presence of a catalyst such as iron oxide (Fe2O3) or silver (Ag).

2Al + 3/2O2 → Al2O3

This reaction is exothermic, meaning it releases energy in the form of heat. The resulting solid product is aluminium oxide.

Both of these methods enable the production and synthesis of aluminium oxide, which is an essential compound widely used in various industries such as ceramics, refractories, catalysts, and electronics.

Safety and Hazards

Chemistry involves working with various chemicals and substances, some of which can be hazardous if not handled properly. It is essential to be aware of potential safety hazards and take appropriate precautions to ensure a safe working environment. Here are some common safety hazards in chemistry:

1. Chemical Spills: Spills can occur while handling or transferring chemicals. Certain chemicals might be corrosive, toxic, flammable, or reactive, posing risks to human health and the environment. Proper containment measures and spill response protocols should be in place.

2. Fire and Explosions: Many chemicals are highly flammable or can react violently when exposed to incompatible substances, heat, or open flames. It is important to keep flammable substances away from ignition sources and have fire safety equipment readily available.

3. Toxicity: Some substances can be highly toxic and may enter the body through inhalation, ingestion, or skin absorption. Proper ventilation, personal protective equipment (PPE), and safe handling procedures are crucial to minimize exposure.

4. Chemical Reactions: Certain chemicals can undergo unexpected reactions, resulting in the release of harmful gases, heat, or explosions. Proper knowledge of the substances being used and their compatibility is important to prevent accidents.

5. Corrosive Materials: Acids and bases are highly corrosive and can cause severe burns or injuries upon contact with the skin or eyes. Appropriate PPE, such as gloves and goggles, should be worn when working with corrosive substances.

6. Pressure Hazards: Some experiments involve working under high-pressure conditions, which can lead to vessel rupture or explosive decompression. Specialized equipment and proper training are necessary to handle high-pressure systems.

7. Electrical Hazards: Electrical equipment and instruments are commonly used in labs. Handling electrical wires and devices with wet hands or in the presence of flammable substances can result in electric shock, fires, or explosions.

8. Inhalation Hazards: Many chemicals can release toxic fumes or gases, which can be harmful if inhaled. Laboratories should have adequate ventilation systems, fume hoods, and employees should use appropriate respiratory protection when needed.

9. Cryogenic Hazards: Working with substances at extremely low temperatures, such as liquid nitrogen or dry ice, requires precautions to prevent cold burns or frostbite. Proper PPE, including insulated gloves and safety goggles, should be used when handling cryogenic materials.

10. Radioactive Materials: Laboratories dealing with radioactive substances must adhere to strict protocols to avoid radiation exposure. Special training, designated areas, and proper shielding are necessary to handle and store radioactive materials safely.

It is important to note that these hazards can be effectively managed through proper safety practices, regular safety training, and adherence to local regulations and guidelines.

Abigail Gutmann Doyle is a renowned Organic chemistry professor in Los Angeles. Her research focuses on the development of new chemical transformations in organic chemistry. She has won awards such as: Bayer Early Excellence in Science Award, Phi Lambda Upsilon National Fresenius Award, Presidential Early Career Award for Scientists and Engineers, BMS Unrestricted Grant in Synthetic Organic Chemistry.